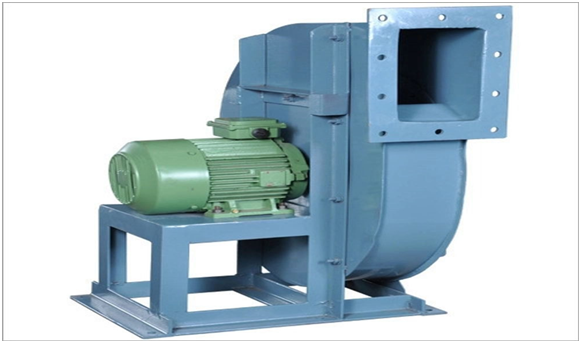

We design and manufacture efficient Centrifugal Air Blower to handle corrosive and toxic gases like

HCl, Cl2, NH3, H2So4, No3, HBr, Br, H2S, HF, H2S, SO2 and SO3, solvent, etc.

We are manufacturing a wide range of Centrifugal Blower. These blowers are fabricated in PP, FRP,

PP+FRP, M.S, SS, PVC. as per the specifications and designs provided by customers. These blowers can

be used for suction of any type of hazardous gases generated from chemical processes. We also

fabricate impellers of blowers as per design and requirements.

We are manufacturing a wide range of PP, FRP, PP+FRP, M.S, SS Centrifugal Blower. These blowers are

fabricated in PP (Polypropylene), PVC (Polyvinyl chloride), FRP (Fibre reinforced polymers), MS

(Mild steel), SS (Stainless steel) as per the specifications and designs provided by customers.

A Centrifugal Air Blower is a type of industrial equipment used for various applications like

ventilation, exhaust, and air circulation.

Centrifugal air blowers use centrifugal force to

increase the speed of air or gas. They are commonly used to move air, exhaust fumes, or gases in

industrial processes.

centrifugal air blowers are often used in

industries where corrosive or aggressive environments are present, such as chemical processing,

pharmaceuticals, galvanizing plants, and wastewater treatment.

The air flow capacity of a centrifugal

air blower can vary widely based on the specific model and size. It is typically measured in cubic

feet per minute (CFM) or cubic meters per hour (m³/h).

These blowers can generate varying levels of air

pressure, measured in inches of water column (in. WC) or Pascals (Pa). The pressure generated

depends on the blower's design and intended use.

The rotational speed of the blower's impeller (the

part responsible for moving air) is usually measured in revolutions per minute (RPM). The speed

affects the blower's performance and efficiency.

The blower is typically driven by an electric

motor. Motor power is measured in horsepower (HP) or kilowatts (kW) and is matched to the blower's

capacity and load requirements.

The size of the inlet and outlet

connections on the blower is important for connecting it to the ductwork or piping of the

ventilation system. These dimensions can vary.

centrifugal air blowers are designed with

corrosion-resistant materials to withstand harsh environments. They are often equipped with

reinforced casings, impellers, and motor housings.

Depending on the application, safety features such

as explosion-proof motors or spark-resistant construction may be incorporated into the design.

Regular maintenance is essential to ensure the

blower's efficiency and longevity. Maintenance tasks may include cleaning, lubrication, and

inspection of components.

These blowers are chosen for

their resistance to chemical corrosion, making them suitable for applications where other materials

may degrade.

Manufacturers often offer customization

options to meet specific requirements of different industries or processes.